“Stopping a production line that produces millions of units per month has a major impact on the business.”

Company B

Company B, which produces the main parts of automobiles, supplies millions of parts per month to automobile manufacturers both in Japan and around the world.

Although the company constantly monitors the condition of its equipment and takes precautions to prevent abnormalities from occurring, it was impossible to completely eliminate the sudden occurrence of abnormalities in the equipment.

Before the pressing process, occasionally the misalignment of a workpiece or a mix-up involving a foreign object occurs. The company tried several countermeasures, such as mechanical changes, various sensors, and predictive detection by AI. However, it was not possible to foresee what kind of abnormality would occur, because there was no clear pattern. Moreover, there was no way to detect a sudden abnormality and stop the equipment in a matter of a few milliseconds.

Under the above circumstances, Adacotech was chosen because we have a track record of detecting intrusion abnormalities with a security company.

Our software was the only service with the ability to solve Company B’s problem. We can generate models by using only normal data (no supervisory data is required in advance) and detect small changes that deviate from normal behavior.

In addition, the AI is constantly trained with the latest data. It learns the latest states of manufacturing processes and adapts to environmental changes in the plant.

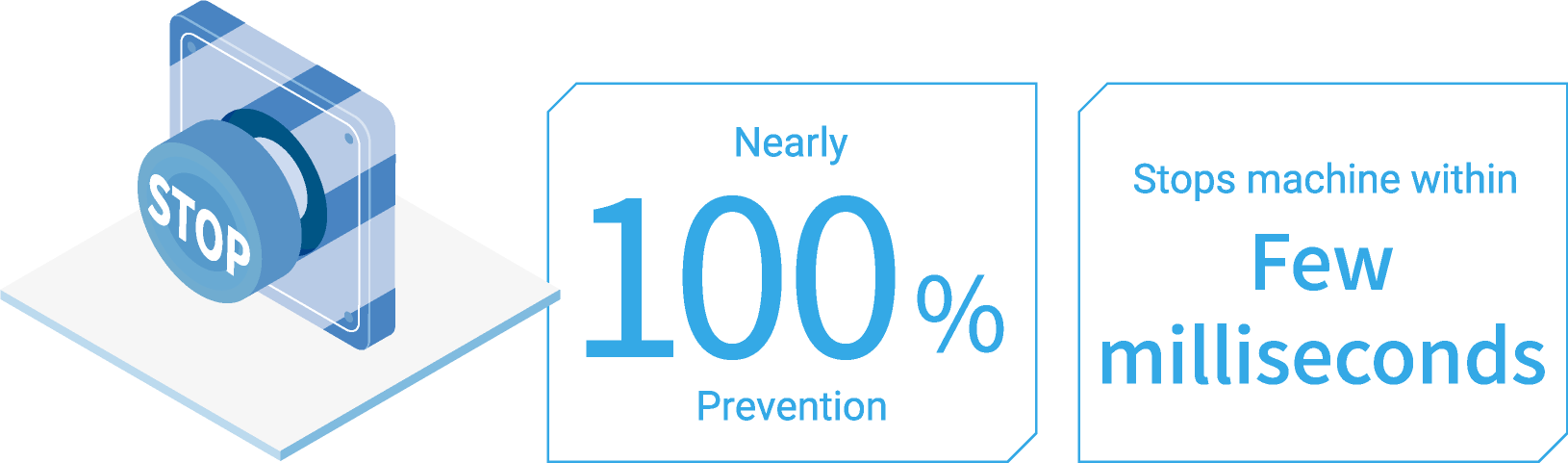

In the event of an abnormality, the system detects it within a few milliseconds, and then stops the equipment.

After six months of operation, we have achieved almost 100% prevention of irregular production. The company is able to avoid damage to molds and ensure operator safety.

“Being able to provide our customers with the promised amount of production at the promised time is the best way to earn their trust. We are relieved to be able to operate without any abnormalities.”

Company B