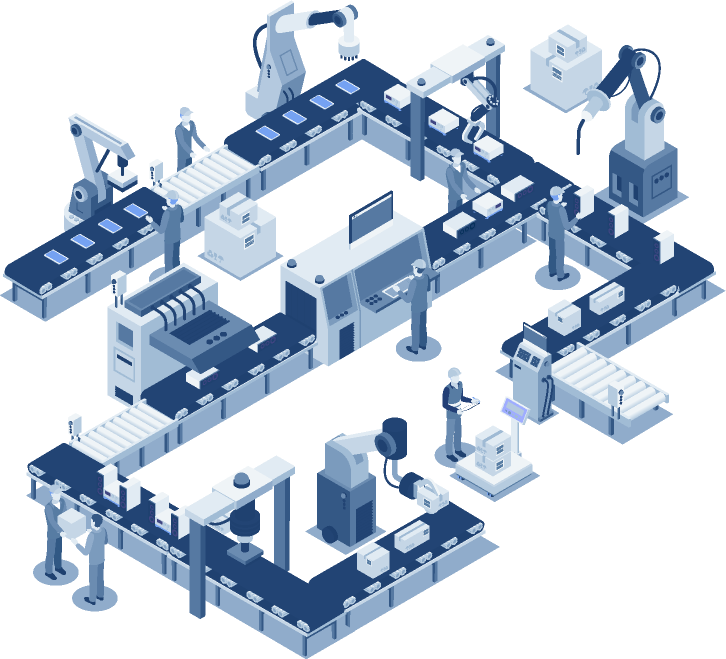

Inside manufacturing plants, various processes related to quality assurance, such as inspection and monitoring of production, are performed by the human senses.

Until now, expert skill of workers was the key to these processes. However, in recent years, labor shortage has become a major issue and passing on of expert skills is harder than ever.

We have created an original AI in order to resolve these issues.

Our mission is to accelerate the evolution and revolution of manufacturing by automating the inspection process.

We provide AI service to resolve various issues related to manufacturing and social infrastructure; issues such as labor shortage in the inspection process, inefficient monitoring of production processes, and ineffective surveillance of social infrastructure.

Our AI operates with 4 types of inputs: image, video, sound, sensors.

We provide anomaly detection technology using interpretable features.

Detects deviation from the normal state.

Works with normal PC (no need for GPU)

Transparent logic (not a "black box")